Also, Each individual Regulatory Compliance Associates pharma consulting Skilled understands compliance enforcement. We’ll prepare an extensive pharma consulting technique to help within your remediation endeavours, push steady advancement, and sustain regulatory compliance With all the restrictions.

Set up Qualification (IQ): documented verification which the tools or techniques, as mounted or modified, comply with the accepted layout, the manufacturer's tips and/or person demands

Internal audits Enjoy a important purpose in guaranteeing the compliance and effectiveness of the company’s operations. In the pharmaceutical industry, this practice is amazingly crucial, because it consists of verifying the producing, storage and distribution of pharmaceutical solutions.

Decrease time and effort when performing audits with automated activity assignments, shifts, alerts and e mail notifications.

Our pharmaceutical consulting Professionals will create a custom-made strategy according to your item and company’s unique wants. Our regulatory compliance clients incorporate:

Products to get reprocessed or reworked needs to be appropriately controlled to forestall unauthorized use.

There must be a composed procedure that defines the situations below check here which a remember of an intermediate or API need to be thought of.

Correct controls ought to be set up in any way phases of manufacturing to be certain intermediate and/or API excellent. Although this guidance starts within the mobile lifestyle/fermentation stage, prior actions (e.

You'll want to read through our short article on pharmacovigilance and update oneself on this essential matter for your health and fitness sector.

Regulatory Compliance Associates pharma regulatory consultants will develop a comprehensive evidence e book of documented proof demonstrating the click here corrective action taken to remediate non-compliant challenges.

If cut-off dates are specified in the grasp creation instruction (see six.forty), these deadlines ought to be fulfilled to ensure the quality of intermediates and APIs. Deviations needs to be documented and evaluated.

Information on the title in the intermediate or API such as, wherever ideal, its grade, the batch quantity, as well as the day of launch must be provided on the certificate of study.

Harvesting techniques, possibly to eliminate cells or mobile parts or to gather cellular elements soon after disruption really should be done in devices and parts built to reduce the risk of contamination.

Supplemental controls, such as the utilization of devoted chromatography resins or additional testing, might be ideal if gear is for use for several solutions.

Michael Bower Then & Now!

Michael Bower Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Katey Sagal Then & Now!

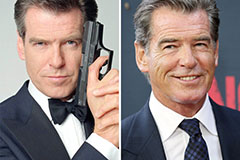

Katey Sagal Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!